Food Grade PE Cling Film Production Process

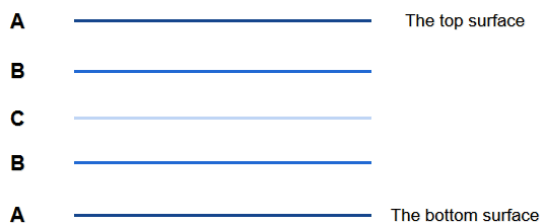

Five-layer co-extrusion casting

There are mainly 3 types of food grade PE cling film in the market: single layer, three-layer, five-layer. JuyouU manufactures the five-layer cling film.

There are more materials can be chose of the multi-layer cling film than the single one, and the materials that meet the requests (Anti-fog/Biodegradable/Antibacterial) can be selected separately, to be endowed with different functions and uses.

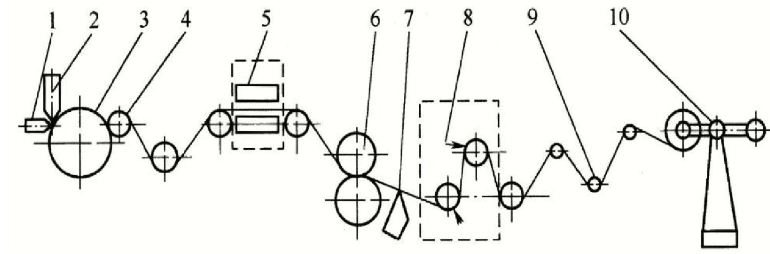

PE Cling Film Production Process

- Machine Head

- Air Kinfe

- Cooling Roller

- Exfoliation Roller

- Thickness Gauge

- Carry-over Pinch Rolls

- Edge Cutting Device

- Corona Treatment Device

- Curved Roller

- Wrap-up Device

Characteristics of extruded flow casting film

1.Production speed is faster than blowing film(30~60m/min), can reaches 60~80m/min.

2.Transparency is better than blowing film.

3.Thickness uniformity is better than bowing film.

4.Longitudinal and Horizontal performance is even.

Thanks for your blog, nice to read. Do not stop.